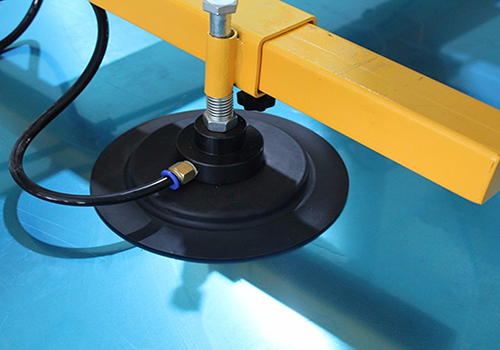

Important considerations for vacuum chuck repair and maintenance

Vacuum suction cup repairand maintenance has always been one of the enterprise’s problems, because of its own complex structure, unique materials, and the working environment of a variety of parameters is extremely complex, today we will lead you to understand the vacuum suction cup daily repair and maintenance.

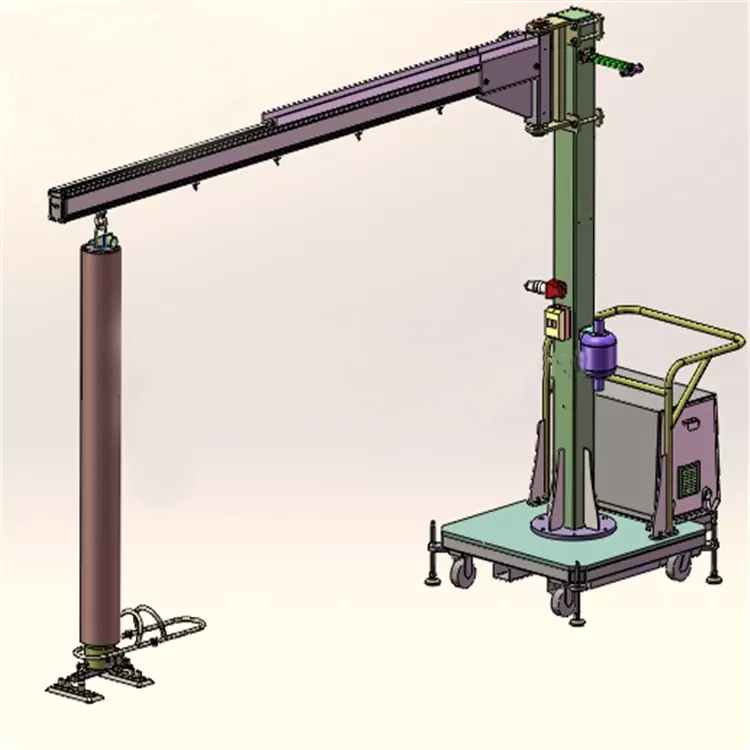

In the case of EOAT using vacuum suction cups (without grippers), it is important to note that the robot must not move at too high a speed, otherwise a shear force will be generated on the suction cups, making it easy for products to fall off during rapid twisting. In some cases, a gripper can be used to ensure the safe transportation of the products. Considering the possibility of the product sticking to the mold, an air clamp can usually be installed to solve this problem. When the surface area of the product is too small or the product is too heavy to use a vacuum chuck, the problem can also be solved by using a clamp.

If the product has very strict requirements for appearance, then the clamped part cannot be the outer surface. To solve this problem, a sensing circuit can be installed. After confirming that the gripper or suction cup has grasped the product, the sensor transmits a signal to the robot so that it can perform the next operation. In cases where the robot’s movement is limited and requires manual twisting or bucking to release the product or move the product and EOAT out of the molding area, the problem can be improved by adding a special cylinder that can move the EOAT on its own, independent of the robot’s operation.

The end tool for in-mold labeling can perform three actions: in a limited space, the EOAT first picks up and inserts the logo, and then fixes the logo in the mold. This operation reduces the size of the unit compared to a static labeling device, and the last action of the EOAT is to remove the labeled plastic bottle from the mold. As a rule, when molding automotive parts, extra care should be taken when working with products with Class A surfaces. The use of vacuum chucks, which are included in the FEU Automation selection, must be absolutely prohibited in order to avoid scratches on their surfaces. At this time, you can consider installing a clamp made of acetal on the EOAT, you can effectively avoid scratching the surface of the product.